Mold Making Steps

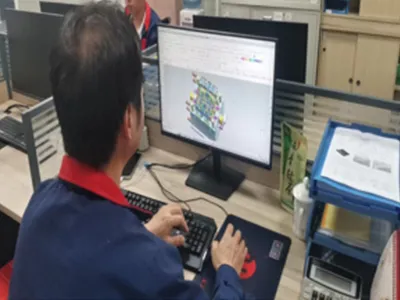

Design

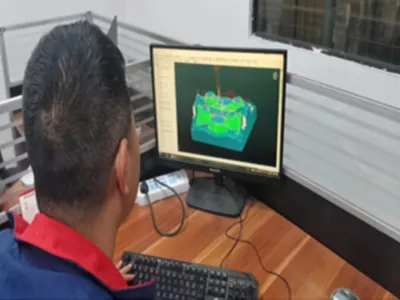

Programming

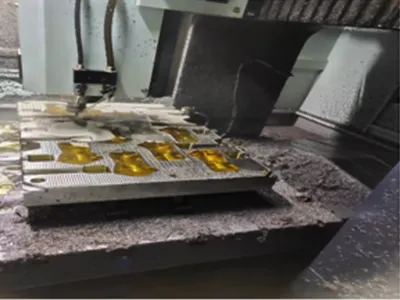

CNC Machining

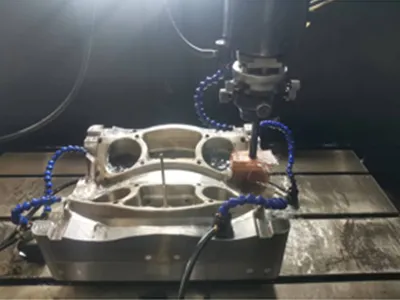

CNC Machine Tool Machining

Precision EDM

Three-Axis EDM

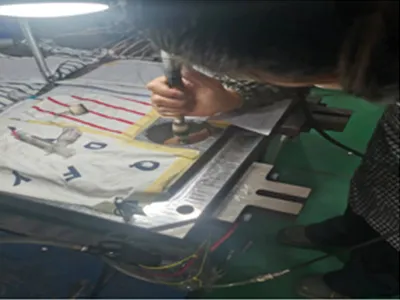

Mirror Polishing

Mold Assembly

01Design

02Programming

03CNC Machining

04CNC Machine Tool Machining

05Precision EDM

06Three-Axis EDM

07Mirror Polishing

08Mold Assembly

Equipment Details

We can design and produce molds

4 high-speed engraving and milling machines

Speed 24000,

stroke 600*500mm

repetitive positioning accuracy (X/Y/Z) 0.005/0.005/0.003MM,

used for electrode copper material processing, processing accuracy ±0.005MM

8 two-line and one-hard CNC machining centers

Speed 12000, taking into account both processing speed and efficiency,

Stroke 1200*700mm,

Repeat positioning accuracy (X/Y/Z) 0.006/0.006/0.007MM,

Used for core steel processing, processing accuracy ±0.008MM

3 CNC-850 mirror EDM machines

800*500mm large stroke,

with C-axis, automatic rotation angle processing, three-axis linkage processing,

processing surface roughness reaches Ra0.13, accuracy ±0.005MM

5 AM120R double-head CNC spark machines

1300*600mm large stroke,

three-axis linkage processing, can process a mold core with two heads at the same time, efficiency increased by 40%,

accuracy ±0.005MM

1 HTC5661 CNC lathe

Speed 3000,

Accuracy ±0.005MM

1 DK77 45 wire cutting machine

Stroke 450*550,

accuracy ±0.01MM

Application

A combination of precision and innovation